Why Predictive Maintenance Is the Future of Fleet Management

Exploring the realm of fleet management, the future lies in predictive maintenance. This innovative approach not only saves costs but also ensures smoother operations for businesses. Let's delve into the fascinating world where technology meets efficiency.

Importance of Predictive Maintenance in Fleet Management

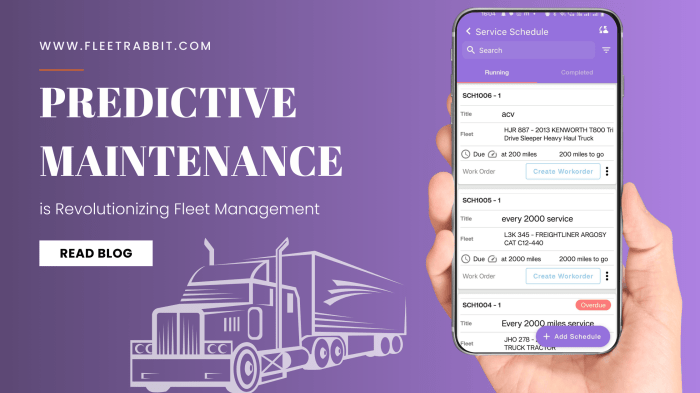

Predictive maintenance plays a crucial role in fleet management by allowing companies to anticipate and address maintenance issues before they escalate into costly breakdowns. By using data analytics and machine learning algorithms, fleet managers can predict when a component is likely to fail and proactively schedule maintenance to prevent unexpected downtime.

Preventing Costly Breakdowns

Predictive maintenance can help fleet managers identify potential issues with vehicles or equipment early on, enabling them to take corrective action before a breakdown occurs. For example, by monitoring engine performance metrics such as temperature, vibration, and fuel consumption, predictive maintenance can detect abnormalities that indicate a failing component.

By addressing these issues promptly, fleet managers can avoid costly repairs or replacements that could result from a sudden breakdown.

Improving Fleet Efficiency and Reliability

Another key benefit of predictive maintenance is its ability to improve fleet efficiency and reliability. By conducting maintenance based on actual condition monitoring data rather than fixed schedules, fleet managers can optimize their maintenance practices to ensure vehicles are always in peak operating condition.

This proactive approach not only reduces the risk of unexpected breakdowns but also helps extend the lifespan of fleet assets, ultimately maximizing uptime and productivity.

Benefits of Implementing Predictive Maintenance

Predictive maintenance offers numerous advantages in fleet management, revolutionizing how maintenance tasks are carried out and transforming the overall efficiency of operations.

Reduction in Downtime and Increase in Vehicle Uptime

- Predictive maintenance allows fleet managers to anticipate equipment failures before they occur, enabling proactive maintenance instead of reactive repairs.

- By utilizing data analytics and machine learning algorithms, potential issues are identified early, minimizing unplanned downtime and keeping vehicles on the road.

- This proactive approach ensures that maintenance tasks are performed at optimal times, preventing costly breakdowns and maximizing vehicle uptime.

Comparison with Traditional Maintenance Approaches

- Traditional maintenance methods often rely on scheduled inspections or reactive repairs based on visual assessments, leading to unnecessary downtime and increased maintenance costs.

- Predictive maintenance, on the other hand, leverages real-time data and advanced analytics to predict equipment failures accurately, allowing for timely interventions and cost-effective maintenance.

- By shifting from reactive to proactive maintenance strategies, fleet managers can reduce overall maintenance costs, extend the lifespan of vehicles, and improve operational efficiency.

Technologies Driving Predictive Maintenance in Fleet Management

Predictive maintenance in fleet management is heavily dependent on various technologies that enable real-time monitoring, data analysis, and predictive insights to optimize vehicle performance and reduce downtime. Let's explore the key technologies that drive predictive maintenance in fleet management.

IoT Sensors and Data Analytics

IoT sensors play a crucial role in capturing real-time data from fleet vehicles, including engine performance, fuel consumption, tire pressure, and more. These sensors transmit the data to a centralized platform where advanced data analytics tools analyze the information to detect patterns, anomalies, and potential issues.

By leveraging IoT sensors and data analytics, fleet managers can proactively identify maintenance needs, schedule repairs before major breakdowns occur, and optimize vehicle performance.

Integration of Machine Learning and AI

Machine learning algorithms and artificial intelligence are integrated into predictive maintenance systems to enhance the accuracy of predictive insights. These technologies use historical data, real-time sensor data, and maintenance records to predict potential failures, recommend maintenance actions, and optimize maintenance schedules.

Machine learning models can continuously learn from new data, improving their predictive capabilities over time. By integrating machine learning and AI, fleet managers can move from reactive to proactive maintenance strategies, ultimately reducing costs and improving fleet efficiency.

Challenges and Considerations in Adopting Predictive Maintenance

Predictive maintenance offers numerous benefits, but it also comes with its own set of challenges that fleet managers need to address. Transitioning to predictive maintenance practices requires careful planning and consideration to ensure a smooth implementation process.

Common Challenges Faced When Transitioning to Predictive Maintenance

- Lack of Data: One of the biggest challenges in adopting predictive maintenance is the lack of historical data needed to train algorithms and make accurate predictions.

- Integration Issues: Integrating predictive maintenance systems with existing fleet management software and hardware can be complex and time-consuming.

- Skill Gap: Implementing predictive maintenance requires specialized skills and knowledge that may not be readily available within the organization.

Strategies to Overcome Obstacles in Adopting Predictive Maintenance Practices

- Invest in Data Collection: Start collecting relevant data early on to build a solid foundation for predictive maintenance implementation.

- Provide Training: Offer training programs to upskill existing employees or hire professionals with the necessary expertise in predictive maintenance.

- Collaborate with Experts: Partner with external experts or consultants who have experience in implementing predictive maintenance in fleet management.

The Importance of Data Accuracy and Reliability for Effective Predictive Maintenance

- Data Accuracy: Accurate data is crucial for the success of predictive maintenance, as inaccurate data can lead to incorrect predictions and maintenance decisions.

- Data Reliability: Reliable data ensures that the predictions made by the system are trustworthy and can help in preventing unexpected breakdowns or failures.

Last Point

In conclusion, Why Predictive Maintenance Is the Future of Fleet Management showcases a transformative shift in how vehicles are maintained. Embracing this technology-driven strategy promises enhanced reliability, reduced downtime, and optimized fleet performance. The future is here, and it's predictive maintenance leading the way.

FAQ Insights

How does predictive maintenance benefit fleet management?

Predictive maintenance helps prevent costly breakdowns, improves fleet efficiency, and enhances overall reliability.

What technologies are essential for implementing predictive maintenance in fleet management?

Key technologies include IoT sensors, data analytics, machine learning, and AI.

What are the common challenges in adopting predictive maintenance practices?

Challenges include transitioning from traditional maintenance approaches, overcoming data accuracy and reliability issues, and strategies to ensure successful adoption.